Westone Sdn Bhd

Established in 1996, Westone Sdn Bhd is a leading manufacturer of PET (Polyethylene Terephthalate) plastic packaging in Malaysia, catering to various industries including food and beverage, personal care, and household chemicals. We prioritise sustainability and invest in automation and advanced technologies to minimise waste and maximise production efficiency. Our automated production lines and quality control systems ensure top-notch product quality and safety. Additionally, we offer customised packaging design services to help businesses improve their brand image. Contact us to learn more about our high-quality and visually appealing packaging solutions.

READ MOREOur Work Process

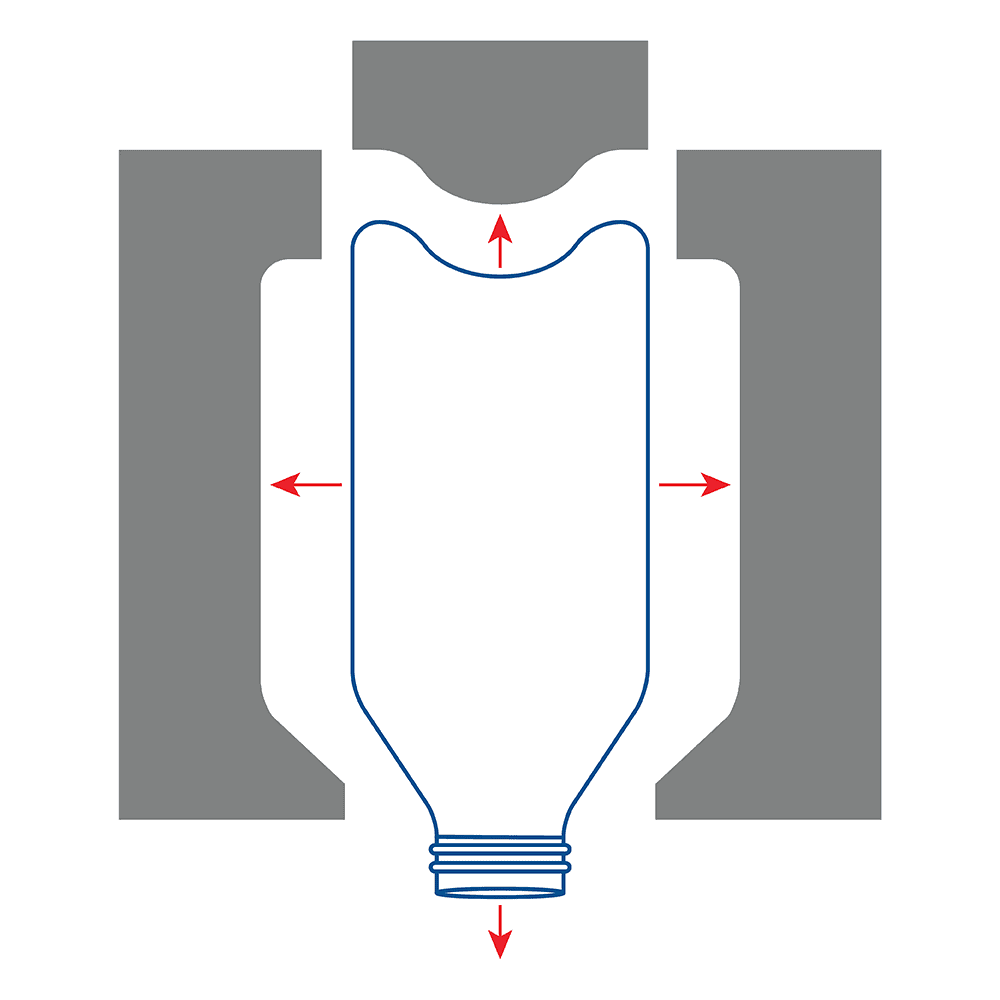

The first step in the 2-step stretch blow moulding process is to produce a preform, which is a small plastic tube-shaped object that will be stretched and blown into the final container shape. Once the preforms have been produced, they are transferred to a stretch blow moulding machine, where they are stretched and blown into the final container shape. The stretch blow moulding process involves the following steps:

Frequently Asked Questions

- PET is the abbreviation of Polyethylene Terephthalate, which is a type of plastic commonly used in the production of plastic packaging. PET plastic is a strong, durable and lightweight material that is resistant to impact and moisture, making it ideal for packaging applications such as cooking oil bottles and chemical bottles.

- Several factors influence the pricing of PET plastic packaging solutions, including:

- Raw Material Costs: Fluctuations in the prices of raw materials, such as PET resin, can impact overall production costs and pricing.

- Manufacturing Complexity: The complexity of manufacturing processes, including mould design and customization, can influence pricing.

- Industry Trends: Overall trends within the packaging industry can influence pricing.

- Operational Efficiency Initiatives: Investments in operational efficiency and waste reduction contribute to overall cost savings, which are reflected in competitive pricing.

- Our company has extensive expertise in the PET plastic industry, complemented by specialized knowledge and insights. In addition, we operate a highly automated production facility, which enables us to consistently deliver high-quality products that exceed our customers’ expectations for reliability, durability, and safety standards. Also, our expertise extends across a broad spectrum of industries, where our PET plastic packaging solutions have set new benchmarks in terms of performance and functionality.

- Yes, we do provide customisation service. We welcome the opportunity to connect with you and schedule a meeting to discuss your unique business needs and explore how we can help meet them.